Quickly Learn How CMMS Barcodes Save You Time And Money

Code 39 barcode font is used by MaintSmart CMMS Software.

Read MoreGet the Best CMMS the Way You Want It: Cloud, Mobile, Web, PC

MaintSmart is Available for Multiple Platforms Use MaintSmart from virtually any platform: PC, Cloud, Web, Smartphone (Android/iPhone). All of the below MaintSmart applications work with the same database seamlessly. Extreme discounts for supported users! Why do we claim MaintSmart is the best CMMS? Comes complete with all modules and nothing to buy later. Available for…

Read MoreMaintSmart 5.1 Suggestions for Our Next CMMS Upgrade

Suggestion box for MaintSmart 5.1 upgrade.

Read MoreCondition-Based Maintenance | Work Orders By Equipment Demand

https://www.maintsmart.com/wp-content/uploads/2019/09/automated-work-orders.mp4 Watch Video in YouTube Condition-Based Maintenance Made Easy! Wouldn’t it be great to have your equipment tell you when it needs maintenance by automatically creating the right work order for the job at exactly the right time? Does this sound too good to be true? Well this is basically what defines condition-based maintenance and…

Read MoreCMMS Software Database Search Tools and Methods

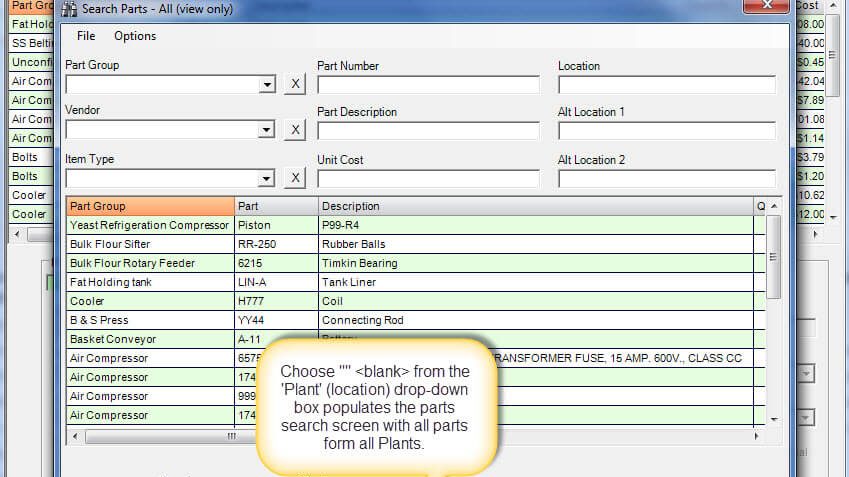

Learn how to quickly and efficiently locate the information you need by effectively searching the CMMS software database with the many search tools provided in MaintSmart.

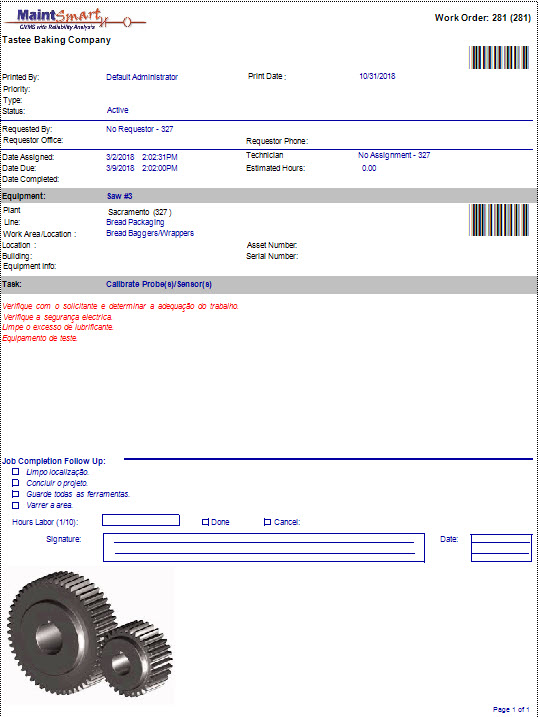

Read MoreWork Order Procedures – 5 Minute CMMS Training Topic

Learn how to use automated formatting tools to build work order, purchase order and preventive maintenance detailed instructions.

Read MoreGenerate Work Orders (7 Ways) – CMMS Evaluation #5

Learn how MaintSmart generates work orders automatically based upon equipment demand and schedules. Free CMMS training video is included with this post.

Read MoreWork Order Tips – MaintSmart CMMS Evaluation #4

Here are a few tips that may speed up work order creation and management. The video below illustrates each of these tips. Subsequent videos will instruct on other way to work quickly and effectively with MaintSmart. https://www.maintsmart.com/wp-content/uploads/2019/08/evaluation-4-1.mp4 FREE CMMS TRAINING VIDEO: Work Order Tips Watch in You Tube Some of the basic tips and shortcuts…

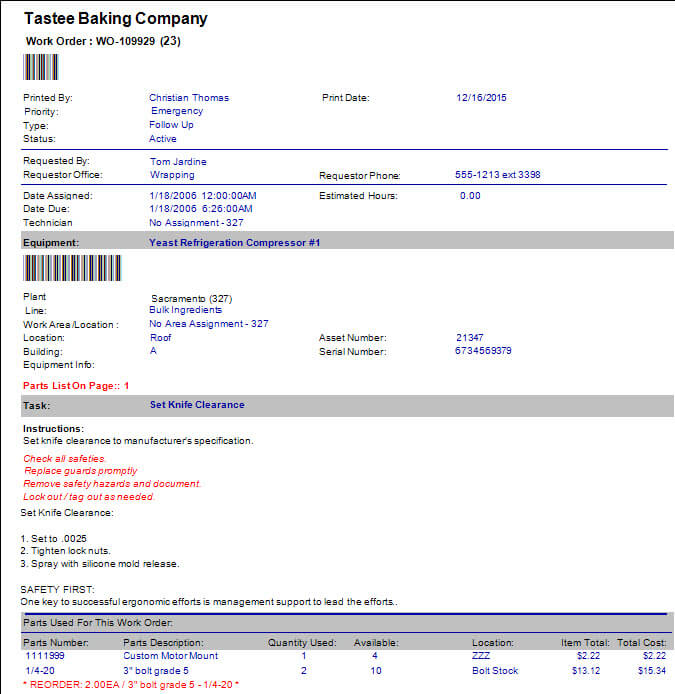

Read MoreCreate Work Orders – MaintSmart Evaluation #3

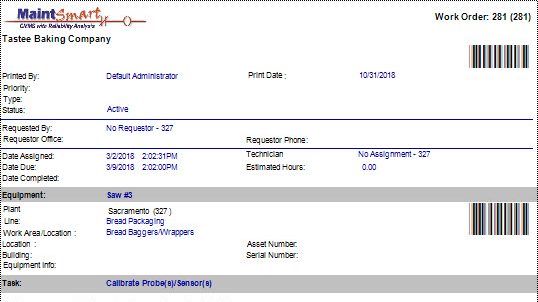

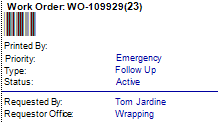

How to Create Work Orders Maintsmart evaluation posting #3 covers creating basic work orders. What is a Work Order? What is a work order? How do you create a work order in MaintSmart CMMS Software? These questions (and more) are answered in this short article and video. Work orders are a unit of work in…

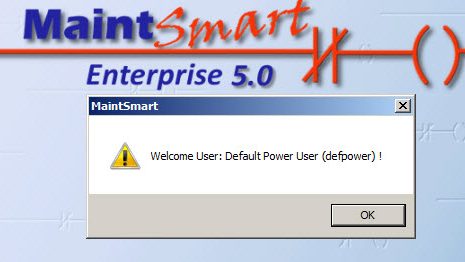

Read MoreCMMS Navigation and User Roles – MaintSmart Evaluation #2

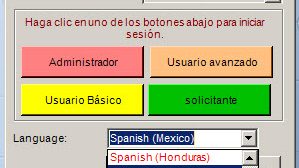

CMMS Navigation Made Simple with Color-Coded Navigation Icons MaintSmart uses an intuitive color-coded navigation menu bar. The icons on the menu bar follow the user to every screen. The obvious benefit of this is that you may always navigate to any screen from the current screen. Additionally, there is no limit to how many screens…

Read MoreCMMS Evaluation Tips for MaintSmart Maintenance Software

Learn how to download, login and navigate MaintSmart CMMS Software.

Read MoreMaintenance PM and Downtime Updates Free to Supported Users

Maintenance PM and Equipment Downtime Updates MaintSmart 5.0.9.9 includes useful new maintenance PM updates. Additional enhancements to downtime and spares usage screens also help speed up data entry and provide improved reporting of CMMS efforts. Features, additions and bug fixes in our CMMS maintenance release version 5.0.9.9 include: Big navigation icons. Improved equipment configuration filtering.…

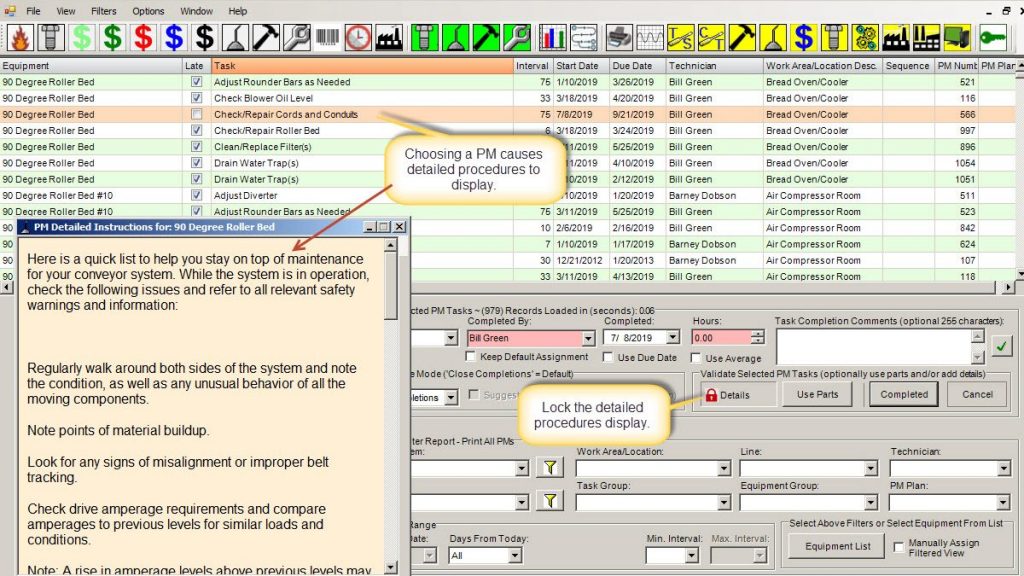

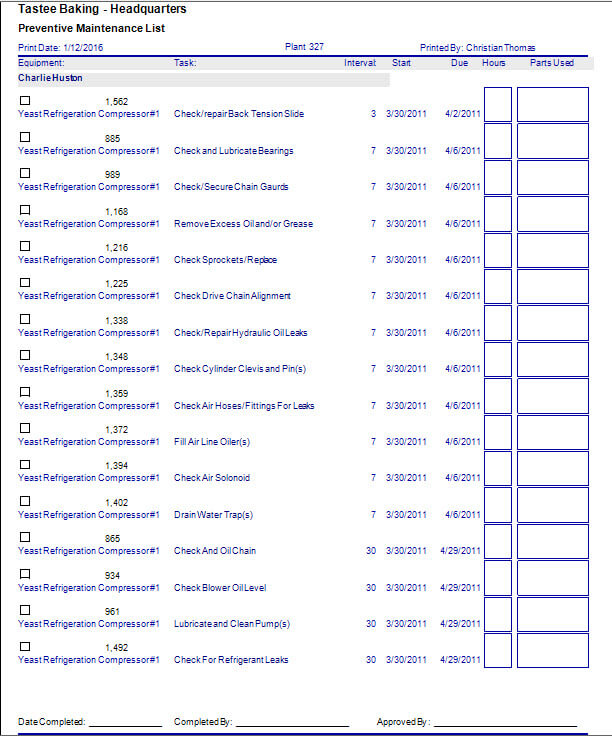

Read MoreClosing Preventive Maintenance Tasks

How to Close Preventive Maintenance Tasks (PMs) MaintSmart CMMS Software has two different ways to create, issue and close preventive maintenance tasks (PMs). Use a full work order generated from a work order template either by a calendar trigger or a meter trigger. Use the PM screen. Create PMs one time and thereafter the PMs…

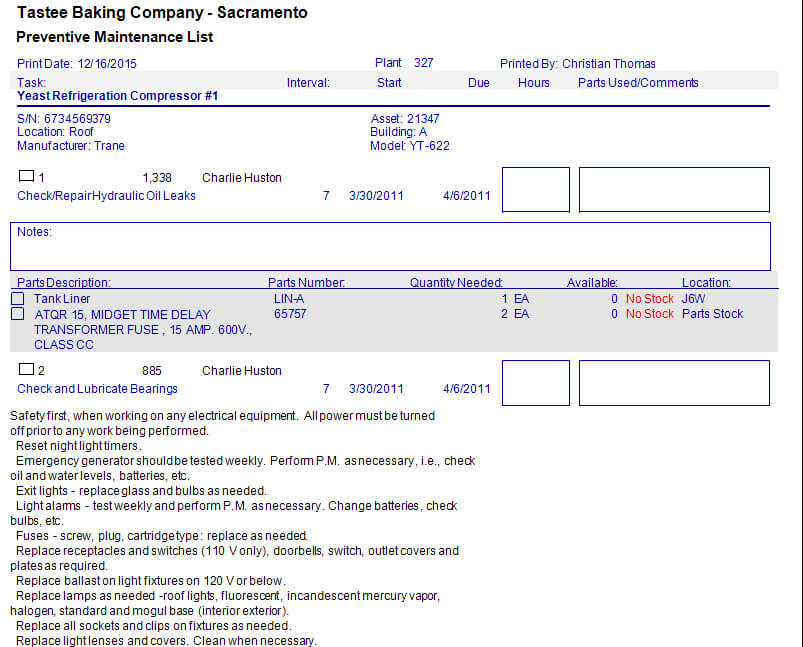

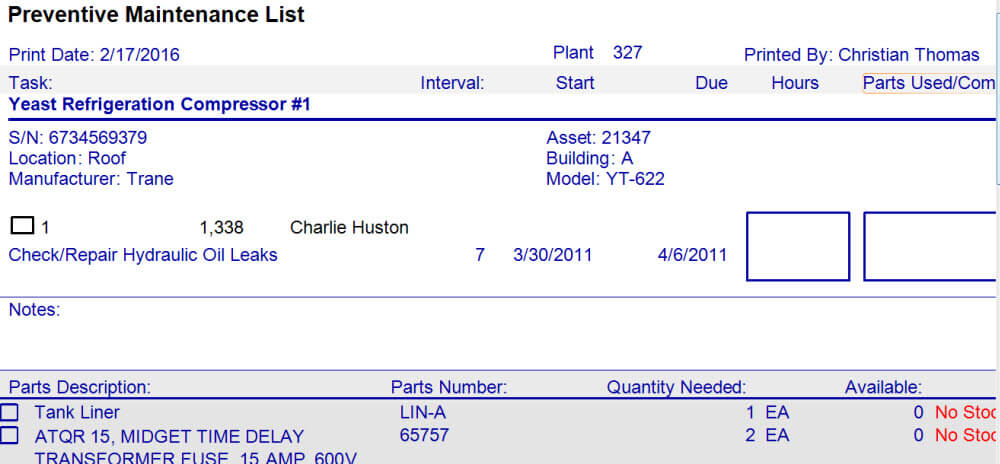

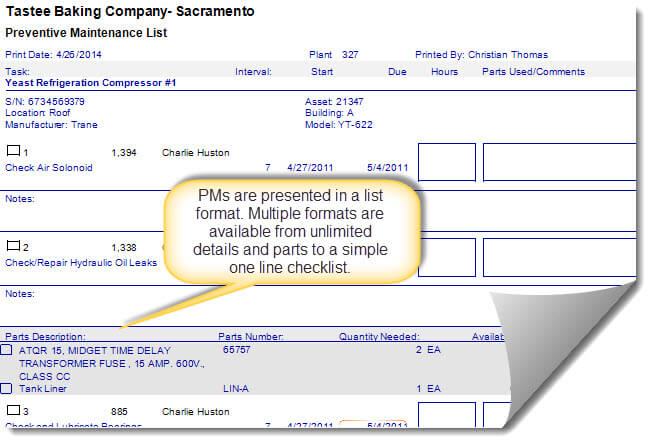

Read MoreFree PM Software Training – Sorting, Filtering and Printing PMs

Free PM Software Training Free PM software training. Learn to filter, sort and print preventive maintenance task lists. Preventative maintenance is a large part of any equipment maintenance management operation. As such, the ability to quickly identify and issue filtered PM task lists is important. This free PM software training post instructs on filtering sorting…

Read MoreCreate Preventive Maintenance Task Lists in 20 Minutes

Create PM Task Lists in 20 Minutes Use MaintSmart CMMS to create PM task lists and build a comprehensive preventive maintenance solution quickly. This video instructs on how to create PM task lists in 20 minutes. Below are the steps for creating equipment, tasks and ultimately the PM tasks lists. Below are instructions for testing…

Read MoreGSA Contract for Equipment Maintenance Software Awarded to MaintSmart

Click Image Above to See the GSA MaintSmart Software eOffer GSA Contract for Equipment Maintenance Software Awarded to MaintSmart The Government Services Administration (GSA) awarded a contract for equipment maintenance software (IT Schedule 70, contract # 47QTCA19D000Q) to MaintSmart. This contract covers pre-packaged equipment maintenance software, training and support for our CMMS software product. Our…

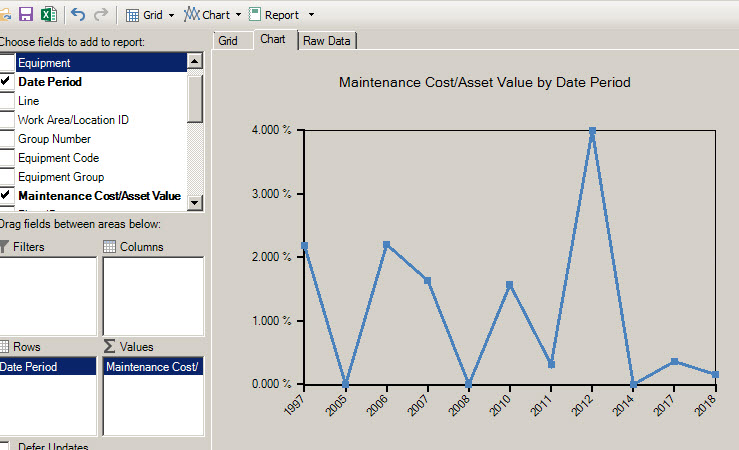

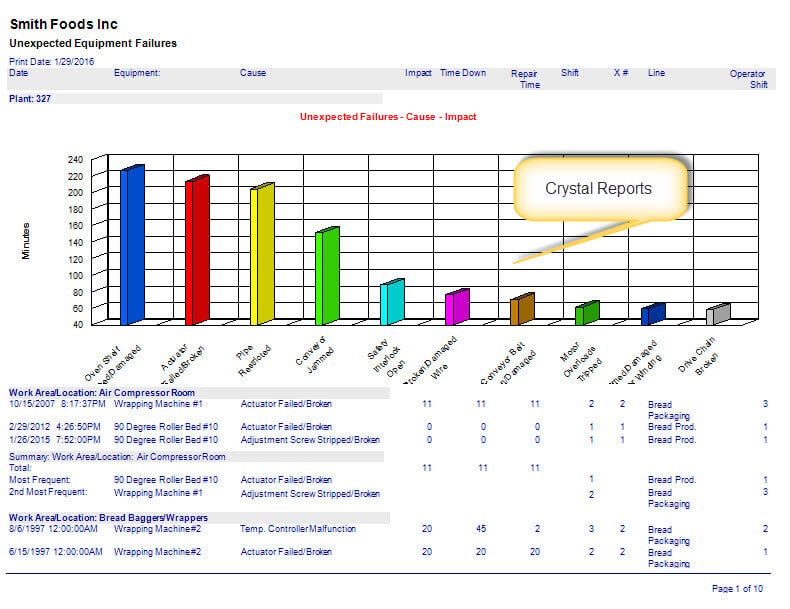

Read MoreCMMS for Maintenance Cost / Replacement Asset Value

CMMS Determines Maintenance Cost / Replacement Asset Value Our CMMS software now offers maintenance cost/replacement asset value as a KPI. Additionally, multiple downtime related KPIs provide a clear path for the maintenance manager that is looking to improve machine reliability. Predictably reducing machine downtime typically offers the greatest potential in immediate improvement. As such, MaintSmart…

Read MoreHow to Add Work Order Images Using CMMS Software

How to Add Pictures to Work Orders Adding pictures to a work order make the task clearer to the maintenance technician and provides a better record of the completed work. Work order images add clarity to the job instructions. Pictures that describe or otherwise illustrate the required work save time and provide powerful documentation. Additionally,…

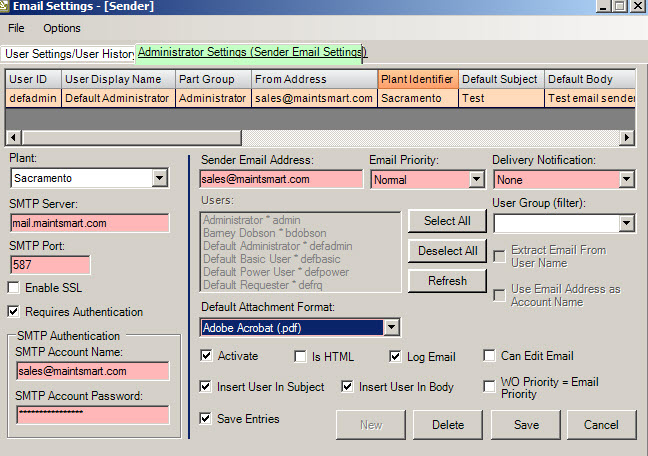

Read MoreMaintenance Scheduling Software | Scheduled Maintenance

Maintenance Scheduling Software Maintenance scheduling software that automatically emails preventive maintenance task lists, work orders or any other report with time-sensitive data. Maintenance Scheduling Software – Automatically Email Maintenance Schedules at Exactly the Right Time Maintenance scheduling software is CMMS software that is used to schedule preventive maintenance tasks, work orders or any other report.…

Read MoreCMMS Reporting | Reporting Equipment Maintenance Data

MaintSmart CMMS Software has many ways to report, including a custom report builder that uses simple drag and drop to create beautiful reports and charts.

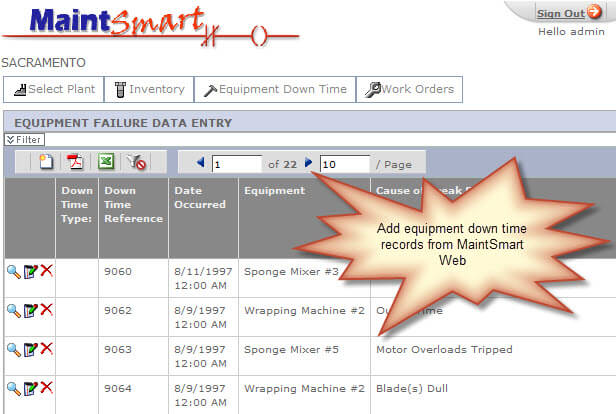

Read MoreWeb CMMS Software

Web CMMS Software This new web CMMS software add-on is a simple and intuitive. Access your CMMS from anywhere at anytime! The new MaintSmart Web Work Requester version 5.0 (web CMMS software system) makes it simple to submit repair tickets and manage work with a tablet computer, or other portable device. This redesigned web-based…

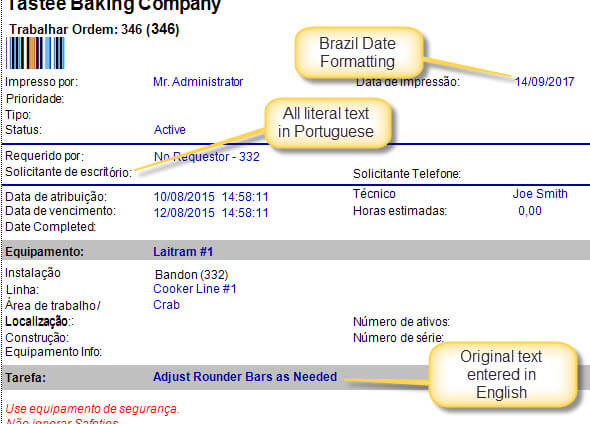

Read MorePortuguese CMMS Software

Portuguese CMMS Software | Translatable CMMS How to Translate CMMS Software to Any Language Portuguese CMMS software is widely is used in Brazil, Portugal, Mozambique, Angola, Guinea, Cape Verde, and other industrialized countries. Unfortunately many of these systems are inadequate when it comes to reporting and analysis of CMMS data. In this example Portuguese is…

Read MorePreventive Maintenance Program Success

Designing an Effective Preventive Maintenance Program Designing an effective preventive maintenance program involves the following steps: Identify your equipment list. Determine equipment run-time requirements. Prioritize equipment by function. Determine required tasks needed for effective PMs. Establish PM interval by calendar day, meter or other interval unit. Quantify manpower versus PM task/hour requirements. Generate the appropriate…

Read MoreAutomatically Create Work Orders

Automatically Create Work Orders – Scroll Down for Free Videos! Automatically create work orders on equipment demand using MaintSmart’s meters component. What is a meter? A meter is a unit of anything you define. Below a a few examples: Every 2000 cuts. At 6000 miles or 6 months. When its been 500 hours since last…

Read MoreReduce Preventive Maintenance Time

2 Simple Ways to Reduce PM Time by 1/2 https://www.maintsmart.com/wp-content/uploads/2017/05/intro-automated-pm-issuance.mp4 Using Roles and Permissions to Enforce Timely PM Task Closing. #1 Automatically Issue Preventive Maintenance Task Lists Use the Print/Email Scheduler to automatically issue exactly the right PMs at exactly the right moment to the the right maintenance tech. This completely frees up the maintenance…

Read More