What is CMMS Software?

To answer the question "What is CMMS software?" requires multi-faceted response and CMMS software definition. The reason for this is that CMMS software performs several functions needed to extend the life of equipment assets. Additionally, this software improves reliability and equipment availability leading to lower lower equipment maintenance costs. Best of all, product quality and consistency is improved,

- Work order management.

- Preventative maintenance management.

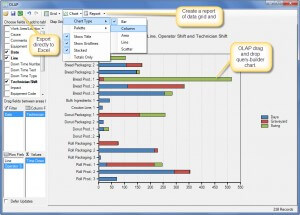

- Reliability and downtime analysis and reporting.

- Purchase order management.

- Inventory (spares) management.

- Work schedule management.

- Event notification (for work, downtime and requisitions)

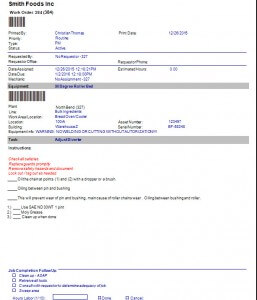

Managing Work Orders

What is a work order? A work order is a unit of work derived from a work request. To clarify, a written repair ticket or a verbal request are both examples of work requests. After the request is received the work order is manually or automatically created by a maintenance manager or maintenance planner. The maintenance team also creates work orders in response to machine breakdowns or other equipment maintenance needs.

Additionally, preventative maintenance work falls into the work orders category. Email, print or open the work order directly from a desktop computer, CMMS smartphone app or tablet computer. Lastly, complete the work, then close the work order with it's corresponding labor hours and parts list.

Managing work orders without a CMMS is cumbersome and time-consuming.

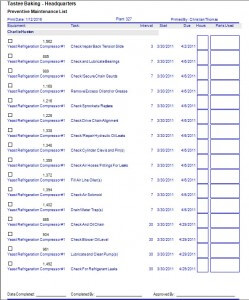

Preventative Maintenance Management

To provide a CMMS software definition preventative maintenance (PM) must be included. What is preventative maintenance? Preventative maintenance is routine periodic maintenance performed on equipment at a specified interval. This interval could be calendar days or some other user-defined unit.the goal of preventative maintenance is to extend equipment life and improve equipment reliability.

Display the preventative maintenance task lists in a list format so that work items are checked off as they are completed. This provides an orderly and intuitive way to assign and manage PM work. Email, print or simply display the preventive maintenance work list. Use the automatic print/email scheduler to send the work list directly to maintenance team members at exactly the right time.

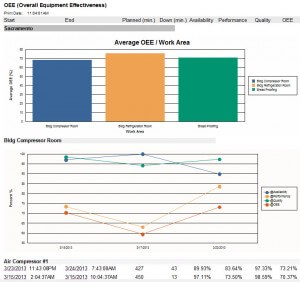

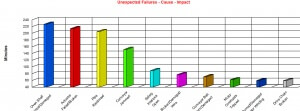

Equipment Downtime Tracking

What is machine downtime? Downtime generally refers to unexpected equipment failures. These failures interrupt the normal course of business and often lead to expensive repairs that could have been mitigated with preventative maintenance procedures.

What reasons are there for tracking downtime?

- Helps identify problem equipment.

- Guides preventative maintenance activities.

- Used to justify equipment replacement or rebuilding.

- Focuses maintenance resources on the greatest cost-saving efforts.

- Used to generate reliability analysis and OEE reports.

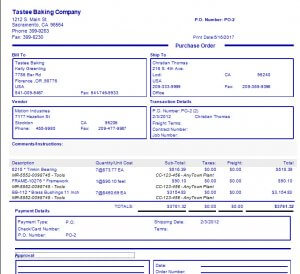

Managing Purchase Orders

Often purchasing is not part of the CMMS software definition. Conversely, many systems focus strictly on work orders and preventive maintenance. The purchase order management software module is included with the CMMS for tracking purchases of spares used on work orders and PMs. What is a purchase order? A purchase order is a way of purchasing from a vendor. Purchase orders are the most common way of purchasing needed items by a commercial entity.

What are the benefits of using purchase orders? Purchase orders provide a listing of items and a standard way of purchasing. Furthermore, track and report on purchase orders later. Additionally, matching paid invoices to purchase orders provides a way to "close the loop" on a purchase.

Purchase orders are contracts to buy in some cases. Each purchase order has a unique identifying number used for tracking. Not all CMMS software packages include a purchasing module. This one does.

Inventory (spares) Management

Use spares to repair or maintain equipment. Spares may be normal consumable items such as filters and lubricants. Conversely spares may encompass unique and expensive parts required for equipment maintenance or replacement. Like the purchasing module, we include a comprehensive inventory management system in our CMMS software solution.

How does my organization benefit from inventory management software? Specifically, it is best to manage spare parts inventory with software for the following reasons:

- Ease of editing quantities and other characteristics.

- Linking to who, why and where the spare parts was used provides useful reporting on equipment costs.

- Though optional, integrating the purchasing module into the CMMS creates a system where spares quantities and unit cost are updated automatically when spare parts are received.

- Restocking is simplified.

- Physical inventory variance and cycle count audits are managed through the software. This reduces paperwork and provides accurate record keeping.

What Methods are Used to Install CMMS Software?

CMMS software is installed is five ways:

- Local desktop computer.

- Desktop computer with database on a server (client server).

- Cloud-based installation.

- Web server installation.

- Smartphone (iPhone or Android) or tablet installation.

By having a diverse range of target devices the CMMS is available to anyone, anywhere. This encourages the use of the CMMS and the subsequent benefits.

What is CMMS Software? (this video answers this question)

Learn how to use create a simple work order.

What are CMMS Benefits?

Like any tool, when used properly, it can increase productivity. CMMS benefits that may be realized with proper use include:

- Ease of work issuance and tracking.

- Tracking employee efficiency.

- Managing equipment reliability and availability.

- Automated issuance of preventative maintenance.

- Reduced equipment downtime.

- Simplified ordering of spares.

- Saving on inventory due to managing stock levels accurately.

- Ease of reporting on all parts of the maintenance operation.

CMMS Software Definition - Other Terms

Other terms used for CMMS software include the following:

- Work Order Software

- EAM Software: Enterprise Asset Management Software.

- TPM Software: Total Productive Maintenance Software or Total Preventive Maintenance Software

- CAFM: Computer Aided Facility Maintenance.

- FAR: Fixed Asset register

- PM program: Preventive Maintenance Software

- Equipment Maintenance Software

- Preventive Maintenance Software

- ERP Software: Enterprise Resource Planning Software (usually CMMS is a portion of the all-encompassing ERP)

- Maintenance Management Software

Contact Us! We want to hear from you.

- Installer password?

- Free help documents and videos?

- Unlimited free CMMS software training during demo period.

- Any questions?

- Pricing for software?

- Free personalized online demonstration?

- Formal quote or proposal?

- Free consultation?

- All suggestions and comments are welcome!

MaintSmart Software, Inc., 66164 Homestead Rd., North Bend, OR, 97459 U.S.A.

+1-541-404-0616 ~ [email protected]